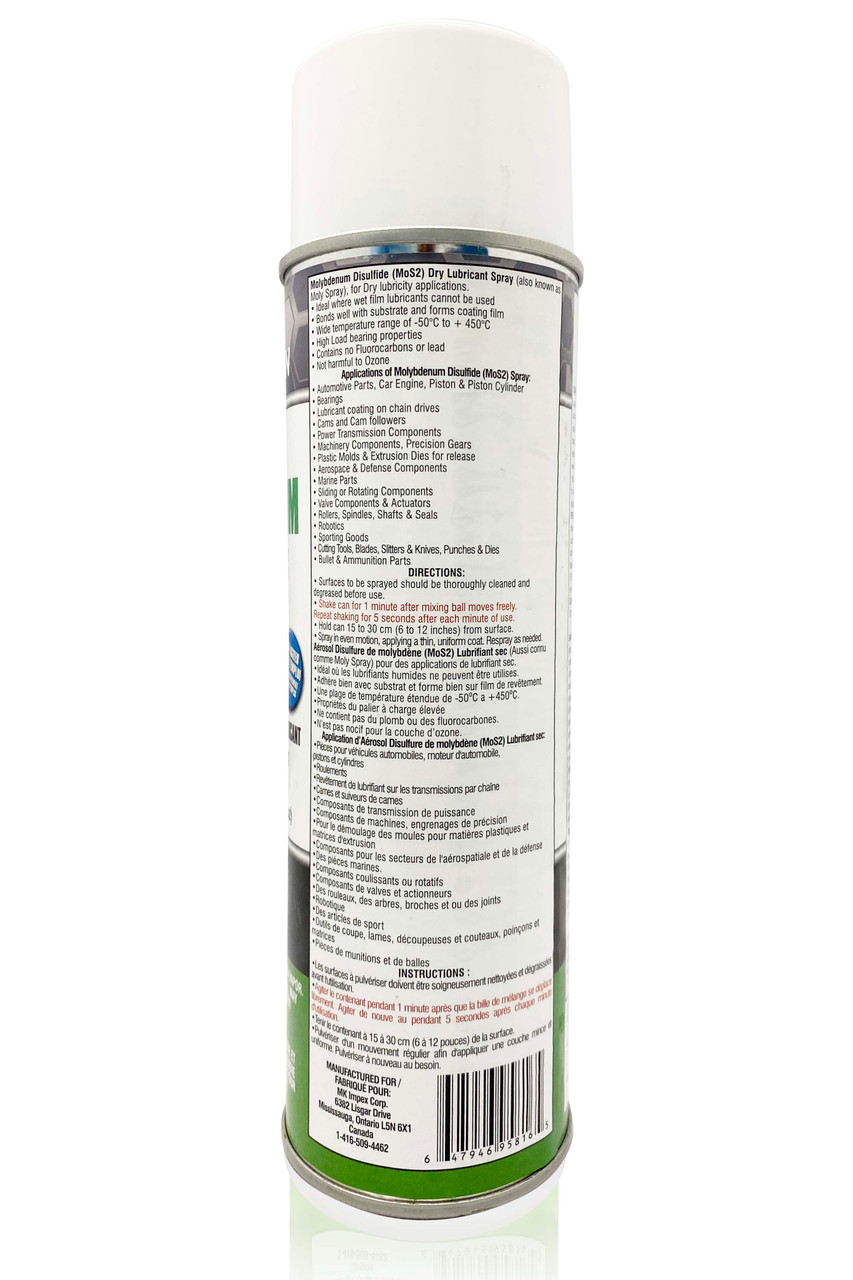

Tips to Optimize the Application of Moly Spray

Moly Spray

The Moly Lube has been a dependable option for industrial process operators as it contains shapes of a beaten dry molybdenum disulfide film. It depicts a much lower scouring coefficient besides suitable disintegration resistance. It is non-smooth, non-shabby, and never cold streams, vacates, or spills.

Loads that the moly spray bears prove heavy as it withstands temperatures ranging from -84 degree Celsius to +400 degree Celsius. It has the capability of bearing 2400-degree-Fahreheit owing to its anti-seizing property.

How the Moly Spray Fits In with the Needs of the Hour

The minute friction coefficient rendered by the film resists wearing it to perfection

It yields support towards a long range of temperature needed for industrial operation

Never sucks dirt and soil

Gets dried quite quickly enabling every component to be ready for processing

Gives the assurance of long term lubrication

It makes its way through the pores of substrate

It holds on to the surface tightly owing to its firm adhesion

Tips to Proceed with the Application of Moly Lube:

You will achieve a durable gasket coat with moly lube, which you may even use for releasing the mold and acting as a thread lube permanently. Alloys, drawings, and extrusions are amongst the various forms of metals that it creates. Furnaces and ovens even get their surfaces acquire the much needed sliding support out of it.

In the absence of competition, the lube gets support for SAP. This dry-film oil is subject to molybdenum disulfide. When fused with metal substrates the molybdenum disulfide structures a solid, low grinding film that gets against wear and disintegration. The spray reduces metal pacing and weathering while portion assembling and dissipating the starting conditions and where standard 'moist' treatments either can't be used or don't yield agreeable oil.

Various industries have found a permanent place for Moly spray owing to its varying capacity of withstanding different operational conditions. What seems more beneficial about them is that they don't get segregated. Unlike the lubes and oils, the dry form of the film will not attract the remaining buildup or soil. Besides, it is impenetrable to water weathering turning it appropriate for use in absurd conditions.