What Modifiers Can Be Added While Producing Acrylic Sheets?

Price of Acrylic Sheets

Acrylic or PMMA (Poly Methyl Methacrylate) is made from MMA (Methyl Methacrylate) and is a synthetic polymer. It has properties like strong, lightweight, tough, impact-resistance, scratch-resistance, transmits 92% visible light and filters UV light.

The properties of acrylic can be modified by adding modifiers. Pure acrylic is rarely used in any applications. Usually, additives, plasticisers, fillers, dyes and reinforcing fillers are added to get the desired property as required for an application. These can be added during the dry blending, compounding or extrusion processes.

Acrylic is used in various applications and the price of acrylic sheets is also lower than other materials like metal, wood or glass. It is impact-resistant and easy to transport and can be used where large sheets are required.

Modifiers added to PMMA

Different additives can be added to either modify a property or enhance a property. Stabilisers and processing aids can also be added. Property modifiers include flame retardant, antimicrobials and impact modifiers.

Plasticisers are added to the polymers to reduce the modulus of a polymer at the use temperature. Though the impact strength and the processing properties will improve. It also helps to lower the glass transition temperature of acrylic.

Fillers are inert materials that are used to reduce the resin cost and improve processing properties. Mica may be added to polymers to improve the electrical and heat-insulating properties. Glass fibers may be added to improve the mechanical properties.

Reinforced fillers are used to improve mechanical properties like tear strength, modulus, abrasion resistance and fatigue strength. Fibers in the form of continuous strands, woven fabric and chopped fibers can be used to reinforce thermoplastics.

Dyes can be added to get the desired colour for decorative purposes or for protection against UV light.

Types of acrylic sheets

The coloured acrylic sheets are in great demand because they are stranger than glass and much lighter. They are long-lasting and this makes them cost-effective.

The fluorescent acrylic sheets appear to glow in diffused light and therefore an external source of light is not required. It is available in various colours and is visually appealing.

The tinted acrylic sheets can be used in any season as they reflect the solar heat and in winter it retains the heat.

The mirror acrylic sheets are used where glass mirrors cannot be used due to their weight. These sheets are more feasible and can be used to amplify the look and safety.

The prismatic acrylic sheets are patterned on one side and widely used in lighting applications. They can be easily cut as per requirement and are easy to install.

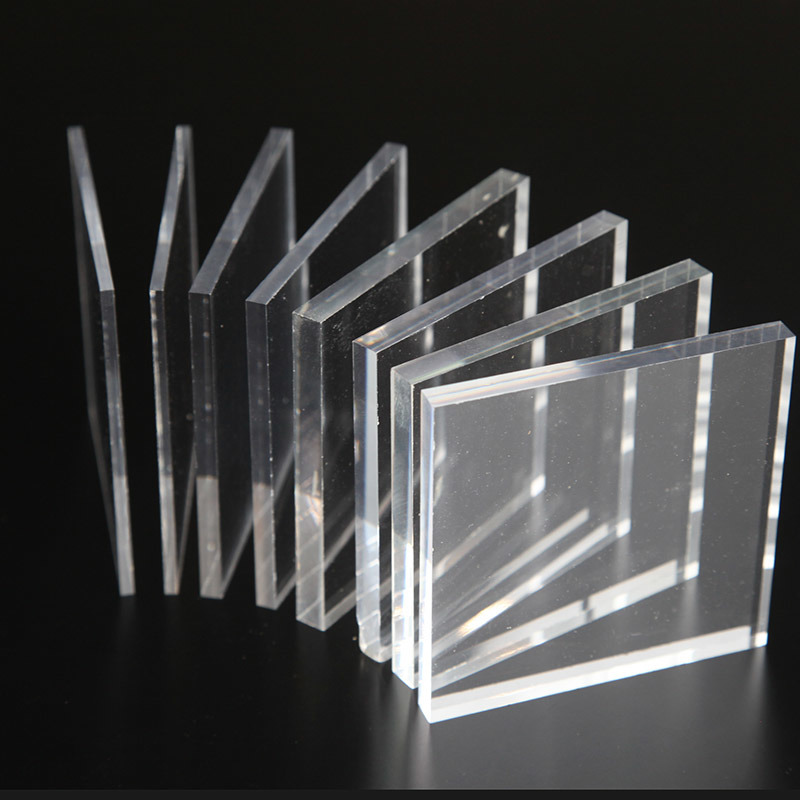

The clear acrylic sheets can transmit up to 92% of visible light. The extruded clear sheets are harder and can be easily moulded.